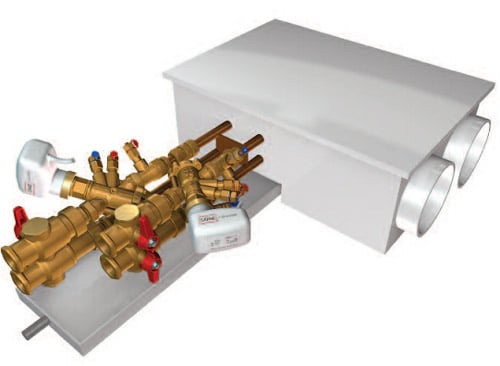

Pre-fabrication takes many guises, ranging from large scale completed rooms such as bathrooms down to smaller items such as FCU’s (Fan Coil Units) pre-fitted with valve assemblies.

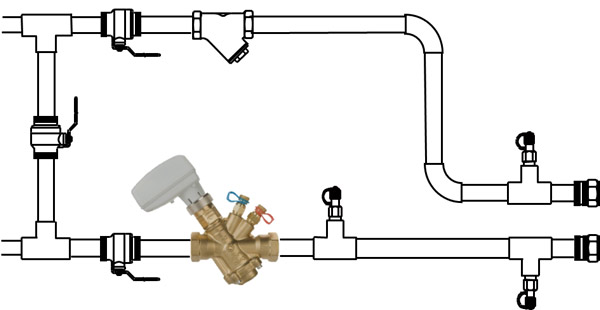

Whilst valve assemblies are a relatively small part of the installation, the quantity of assemblies gives the contractor an opportunity to save on his installation time.

The Dominator Series

The Dominator was the first purpose manifold assembly to be introduced into the Building Services industry.

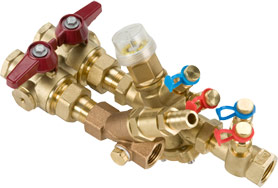

Until then, valve assemblies were a combination of standard valves assembled into a copper framework.

From the original Dominator, which is installed ‘remotely’ from the coil and had 80mm pipework centers, the Dominator PRO was developed.

The Dominator PRO is designed to fit directly onto the copper tails of the FCU coils, having 40mm centers, above the condensation drip tray. This allows for the valve sets to fit within the increasing demand for reduced ceiling void spaces.

Both the original Dominator and the Dominator PRO assemblies are based on a ‘mix & match’ approach, therefore allowing the finished assembles to match the individual requirements of the contractor.

They are all pre-pressure tested and labelled with locations before dispatch to site.

Using the Crane FS Dominator not only saves installation time and reduces the product footprint but simplifies the ordering process, allows phased delivery direct to site if required and reduces the risk of failing joints as all Dominators are fully tested as part of the assembly process.

Typical ‘on-site’ installations require up to 28 individual joints

The Dominator and Dominator PRO both only require 4 on-site joints

Where the Dominator PRO is issued directly to your individual Fan Coil Unit manufacturer, the on-site connections are reduced to 2.

View Dominator Product Range