Check Valves are completely automatic in action, depending upon pressure and velocity of flow within the line to perform their functions of opening and closing. You can install most Crane FS swing check valves in horizontal or vertical upward flow piping. Lift check valves must be used in horizontal lines only.

Crane FS offers four basic types of bronze check valves

1

Horizontal Lift Check

2

Vertical Lift Check

3

Swing Check

4

Double Check

CHECK VALVES FEATURES & BENEFITS

When selecting valves, reference to codes of practice and other mandatory specifications should be made which may preclude certain types for specific applications.

Swing Check Valves

Swing check valves, having 6 diameters of straight lengths of pipe upstream and 3 diameters downstream, are suitable for velocities up to 3 metres / second. If the valve is situated such that turbulent flow enters the valve, the velocity should not exceed 2 metres / second.

Horizontal Lift Check Valves

Horizontal lift check valves are used primarily for air, gas and steam services whilst swing check valves are most suitable for water and other liquids. For air, gas and low pressure applications, especially where bubble tight closure is required, a valve with rubber faced disc is necessary.

Compressed air service requires a horizontal lift check valve with a nitrile rubber facing on the disc and fitted with a recoil spring. The valve should always be installed as far away from the compressor as possible.

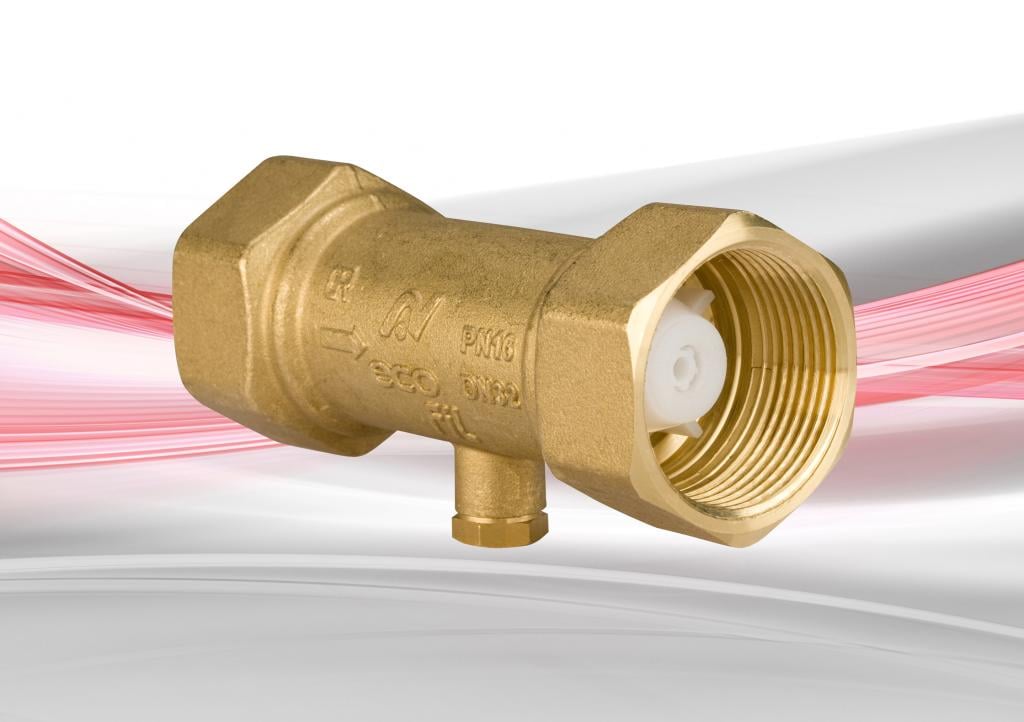

Double Check Valves

Double check valves are designed to prevent contamination of water caused by back syphonage, back flow and cross connection in supplies such as those to hose taps, cisterns, stand pipes, showers and basins.