Variable speed pumps allow the flow rate in the system to fluctuate in response to system demand, by responding to information from the BMS system, which gathers information from thermostats and pressure sensors.

The Crane Fluid Systems PICV range combines the functions of the DPCV, flow regulation, and 2 Port Control valves, into a single valve which:

- Reduces the number of valves

- Reduces installation time

- Reduces number of joints / potential leaks

- Simplifies selection

- Simplifies commissioning

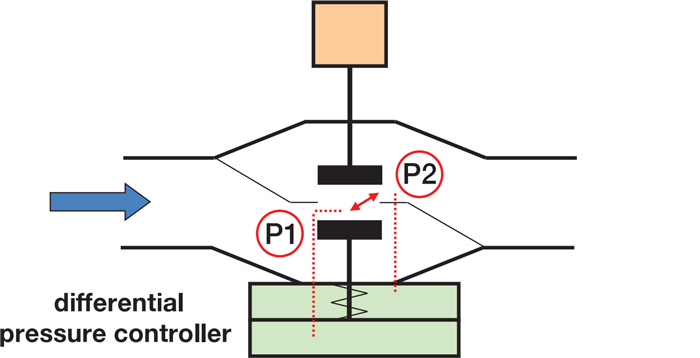

1. Differential Pressure Control

As the flow rates in the distribution pipework fluctuate to match demand, the available pressure at individual terminal units varies. This variation in available pressure has the effect of changing the flow rate through the terminal sub-circuit, i.e. an increase in pressure gives an increased flow rate. To negate these fluctuating pressures, the PICV maintains a constant pressure drop across its seat P1 to P2, therefore maintaining a constant flow rate to the terminal.

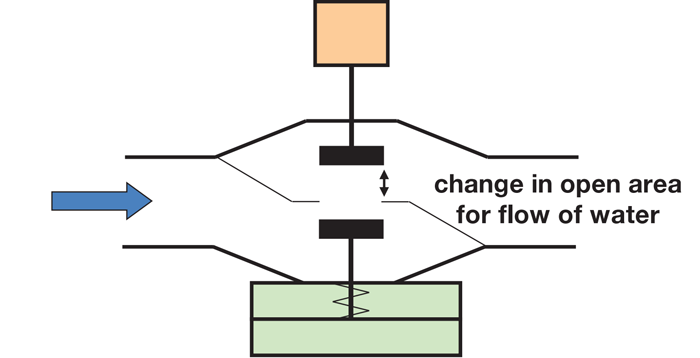

2. Flow regulation

By changing the open space through which the water flows within the valve, the flow rate can be adjusted and set. The pressure across the seat of the PICV is held constant by the differential pressure controller. Whilst setting, the open area around the disk will change resulting in a change to the flow rate. The new set flow rate recreates the constant seat differential pressure P1 to P2. Having set a new flow rate, it will stay constant at the new set value.

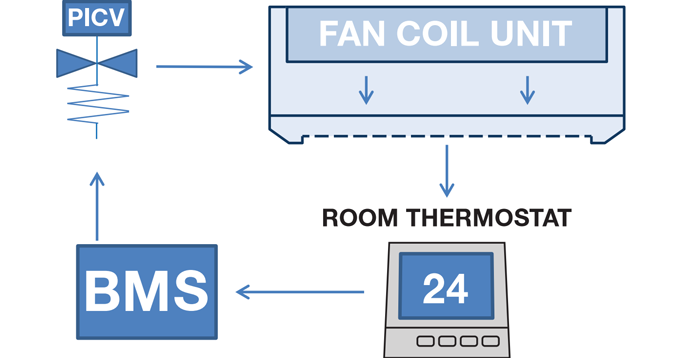

3. Comfort Control

The use of a PICV, as with all 2 port control valves, allows for the variation of the flow rate to vary the heat output of the terminal unit. The PICV is an integral part of the control loop. Thermostat, BMS, PICV & terminal unit. By varying the flow rate we can control the heat output of the terminal. For PICVs with an equal percentage characteristic, (see page 5) there is a direct relationship between valve position and heat output, i.e. half open = half heat output.